M.E.S / M.O.M

Manufacturing Execution System / Manufacturing Operations Management

Caption

M.E.S / M.O.M

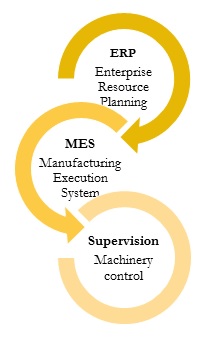

MES/MOM is a shop floor information system that enables you to collect the full range of production data in real time, from raw material acceptance to finished product shipment. This in turn helps you to reduce your costs and enhance your performance.

MES/MOM constitutes the link between ERP, which coordinates the full range of the company’s activities, and supervision software, which controls shop floor production equipment.

MES/MOM MEETS SHOP FLOOR REQUIREMENTS

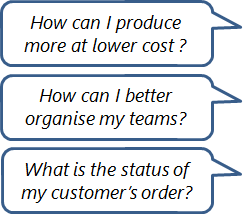

MES/MOM enables you to set up very precise indicators to closely track production. This gives you better control of such parameters as costs, manufacturing capacity, energy consumption and waste management.

MES/MOM enables you to better assign skills and tasks and better manage contingencies. It gives you the precise, real-time data you need to support decision-making.

MES/MOM keeps you abreast of the progress made on each order and updates your production schedule in real time.

MES/MOM: CONCRETE APPLICATIONS

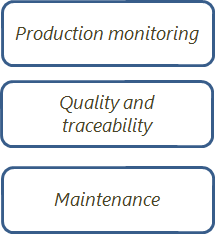

Measure the performance and efficiency of your production facility in real time. Track your OEE (Overall Equipment Effectiveness), organise production operations to ensure on-time delivery and monitor personnel and equipment workload to achieve better management of the full range of your resources.

Track inventory, processes and work flows – from raw material acceptance to product shipment – to control product quality, reduce process variability and ensure compliance with standards and regulations.

Improve the responsiveness of your maintenance teams, track their work and manage preventive and predictive action. With a better overview of contingencies, you can better control your equipment.

ACTEMIUM'S EXPERTISE

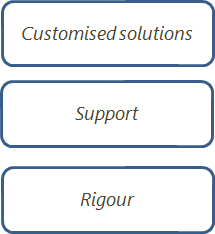

We have longstanding experience with the main commercial MES/MOM solutions and can therefore help you make the choices best suited to your needs and budget. We program the functional modules to address your specific issues.

The introduction of a MES/MOM system is a fully-fledged company project. We support you throughout the process, from specification drafting to employee training.

Regulations are central to our methodology: we work with a Project Quality Plan and meet the requirements of standards including ISO 9001, S95, ISA95 and S88.

MES FOR ALL SECTORS

Food processing

- Production cost control

- Reduced lead time

- Traceability and quality

Pharmaceuticals

- Electronic batch file

- Serialisation

- Weighing station

- 21 CFR part 11 standard

- Audit trail

Manufacturing

- Counterfeit control

- Serialisation

- Quality monitoring

- Real-time OEE

Caption

Functions

MESA, the US-based Manufacturing Execution System Association, has defined 11 MES/MOM functionalities. The classification sets out the coverage of the various MES/MOM systems and provides an overview of the capabilities of this type of software.

Of course, not all industrial sectors will require all the functionalities. Actemium therefore offers modular, completely customisable solutions.

DATA COLLECTION AND ACQUISITION

Collect and secure raw production, quality and safety data

- Acquisition from the factory floor

- Automatic or manual collection

OPERATIONS / DETAIL SCHEDULING

Reduce set-up time, know the precise utilisation of each resource

- Operations sequenced by priorities, attributes, characteristics and / or recipes

- Visual display of sequencing

- Accommodation of alternative paths, overlaps, etc.

LABOUR MANAGEMENT

Organise and coordinate teams

- Personnel status in real time

- Time and attendance reporting

- Skill and certification management

RESOURCE ALLOCATION & STATUS

Know and optimise the company’s resources: machines, tools, labour skills, raw materials, etc.

- Reservation and dispatching to meet operation scheduling objectives

- Detailed history and status in real time

DISPATCHING PRODUCTION UNITS

Update the production schedule

- Flow management: orders, batches, lots, work orders

- Information presented to the various work stations

- Change to meet contingencies and feedback to sequencing (completion status, delays)

- WIP management

PRODUCT TRACKING & GENEALOGY

Ensure compliance with standards and regulations, meet customer requirements

- Process traceability: status, WIP

- Product genealogy

- Centralisation of all information: components, raw materials, suppliers, lots, serial numbers, current production conditions, alarms

QUALITY MANAGEMENT

Improve quality management and response time in the event of a problem

- Real time analysis of measurements collected

- SPC/SQC tracking

- Management of off-line inspection operations

- Management of laboratory information (LIMS)

- Recommended corrective action

PROCESS MANAGEMENT

Take rapid action to improve in-process activities, decision support to ensure compliance following a problem

- Production monitoring

- Automatic correction of process changes outside tolerances

- Management of some or all resources

- Management of alarms

PERFORMANCE ANALYSIS

Provide up-to-the-minute reporting to optimise production

- Real-time tracking of product and operation indicators: resource utilisation, resource availability, product unit cycle time, SPC/SQC

- Periodic real time or deferred reporting

- Comparison with past history and/or expected business results

DOCUMENT CONTROL

Use and share the same technical documents

- Compliance check of files and forms: work instructions, recipes, drawings, standard operating procedures, part programmes, etc.

- Transfer of information between resources

MAINTENANCE MANAGEMENT

Ensure availability of production equipment and tools

- On-time initiation of periodic and preventive work

- Event log, failure register

- Diagnostic support tool

Caption

Who uses MES/MOM?

The introduction of MES is a fully-fledged business project that must cover the needs of all shop floor personnel:

GENERAL MANAGEMENT

Questions you ask yourself:

- How can I produce more with less?

- Why is ERP insufficient?

- What is my daily production, in real time?

- How much does this production cost?

- How can I obtain precise and reliable production information?

MES enables you to:

- Centralise all production information

- Set up indicators to track production status in real time

- Coordinate production and ERP

This gives you better control over:

- Costs

- Capacity

- Production plant and equipment

- Energy consumption

- Waste management

PRODUCTION MANAGER

Questions you ask yourself:

- What operator skills are needed?

- How should the teams be organised?

- Is every task affected?

- Are delivery times being met?

- What slippage is there, if any?

MES enables you to:

- Centralise production information

- Set up real time performance indicators

- Manage resources

- Reduce data input

This gives you better control over:

- Assignment of skills

- Team organisation

- Contingency management (absences, shortages, resources)

- Lead times

- Raw materials consumption

OPERATOR

Questions you ask yourself:

- What should I do now?

- Why do I constantly have to fill out work sheets?

- Where are the documents I need? Are they up to date?

- Have I achieved the objectives set for the day?

- Do I have time to re-work a non-conforming part?

MES enables you to:

- Avoid spending time on tracking

- Display changes in the day’s indicators in real time

- Respond with full information to a problem

- List tasks that are constantly updated

- Track concrete objectives in real time

- Reduce data input time

- Have a better overview of the production process

- Make the most of your skills and take on more responsibilities

MAINTENANCE MANAGER

Questions you ask yourself:

- What is the failure rate of each piece of equipment? How can failure be avoided?

- Do we have the spare part?

- When is the next production shutdown planned?

- Who will be available to do the job?

MES enables you to:

- See the details of down time (by cause, by machine)

- Immediately sound the alarm in case of slippage

- Know the operating parameters

- Transmit production and maintenance schedules

You can thus:

- Prevent equipment failures, stoppages and malfuntions and analyse them (history, hierarchy) to gain a better understanding

- Monitor production indicators

- Improve equipment reliability and increase equipment and tool availability

- Manage and plan maintenance work

- Work closely with production teams

SALES MANAGER

Questions you ask yourself:

- What is the status of my order?

- How can I notify the customer if there is a delay?

- Is the information reliable?

- What alternative can I propose?

MES gives you information about:

- Current status of each order

- Production schedule, updated in real time

- Value of inventories (quantity, location), movements of raw materials between warehouses and production shops and WIP inventory status

- Quality level at all stages of production

QUALITY MANAGER

Questions you ask yourself:

- Does production comply with the customer’s specifications?

- How can the quality rate be improved?

- How can re-working and scrap be reduced?

- Is production compliant with all procedures and regulatory requirements?

MES enables you to:

- Analyse malfunctions

- Develop processes and track their use in real time

- Work closely with maintenance teams

- More easily comply with customer specifications, regulations, traceability requirements, quality processes, certifications and limits on waste generation

Caption

What is MES/MOM?

MES/MOM is a shop floor information system. It enables you to collect full production data in real time and set up very precise indicators that will help you optimise your performance.

To explore the range of MES/MOM applications go to: MES/MOM at a glance

What can MES/MOM do for me?

MES/MOM provides you with information that enables you to optimise your production operations, from the start of the production run to the shipment of the final product. It enables you to improve your performance by boosting:

- Resource availability

- Equipment efficiency

- Production quality

When your production schedule is matched as closely as possible to the reality on the shop floor, you can:

- Organise production

- Track your OEE (Overall Equipment Effectiveness) in real time

- Smoothen the operator and equipment workload

- Anticipate contingencies on the ground

- Guarantee delivery times

- Reduce data input by operators

- Achieve greater product traceability

I already have a very good ERP, what more can MES/MOM do?

MES/MOM and ERP do not cover the same requirements. ERP is an enterprise software package involving both accounting and HR, while MES/MOM is used on the shop floor to provide a real time overview of production operations.

The MES/MOM and ERP systems collect and use their own specific data and also share common data on such parameters as traceability and quality. However, their data modelling granularity differs.

The information collected by MES/MOM is far more precise and detailed: while ERP is based on theoretical nomenclatures, MES/MOM is connected to shop floor equipment and can track a specific product in real time.

Ultimately, MES/MOM and ERP complement each other; data collected by MES/MOM can be fed into ERP.

Can my supervision cover MES/MOM functionalities

Supervision software, which is designed to control machines (for example by tracking the level of liquid in a vat, the lubrication of an engine or the operation of an actuator), is of interest to the machinery operators and line supervisors; MES/MOM is a broader system used by the production management and all relevant company personnel.

Supervision software operates at functional level, while MES/MOM offers broader functionalities that manage production systems rather than single machines.

How do I go about choosing an MES/MOM system?

MES/MOM must be a company project. Senior management often heads an MES/MOM project and all personnel involved in the MES/MOM system must take part in it.

To select an MES/MOM solution, start by defining the functional coverage of the software package: what modules will you need? Are you required to ensure the traceability of your products? Do you want to include quality control? Once you have done this, you can draft a specification to serve as the basis for defining the solution.

Other criteria that may be important to include:

- Modular structure. If your production shop floor changes, you will no doubt require further functions. With a modular software package, you will not be obliged to buy an entire package at once but can add on modules to meet your needs as they arise.

- Project references. Actemium’s MES/MOM expertise goes back 20 years. Actemium has introduced MES/MOM solutions in many manufacturing sectors for companies with several sites or only one site.

How much does an MES/MOM system cost?

The price of an MES/MOM project is determined primarily by two criteria:

- The price of the licence, which depends on the number of sites and users equipped

- The cost of the various services: functional scope (i.e. the specific modules introduced), specific developments to be implemented, employee training, etc.

What is the return on investment of an MES/MOM system?

The introduction of an MES/MOM system can achieve payback very rapidly.

The potential ROI depends on the activity and the sector. It is estimated that tracking OEE (Overall Equipment Effectiveness) in real time can generate productivity gains of up to 15%.

Who should manage the introduction of an MES/MOM system?

MES/MOM must be a company project. It should be overseen by top management and involve all shop floor personnel and all stages of production, from raw material acceptance to production, quality control and product shipment.

To ensure the successful introduction of an MES/MOM solution, it is crucial to put together a team that can be fully dedicated to the project for a period of several months.

It is also necessary to focus on change management, i.e. briefings and training for operators ahead of time to boost acceptance, communication of the project’s objectives and advantages, etc.

Actemium, which is ISO 9001 certified, works with Project Quality Plans (PQP). We use an iterative methodology to support you at all stages of your project – specification, analysis, training, integration, testing and validation.

How long does it take to complete an MES/MOM project?

The introduction of an MES/MOM solution is a large-scale project that will monopolise a team for several months. The team will need to prepare the project ahead of time, prior to drafting the specification, and will focus on change management, notably by conducting information briefings and training for employees.

Using the methodology based on its 20-year experience, Actemium supports you at all stages of this project. Our specialised MES project managers are well versed in all shop floor jobs. They work alongside you, on the ground, to provide the advice you need to ensure the success of your MES/MOM project.

How do I manage an MES/MOM project in a multisite environment?

MES/MOM provides a common solution covering all your production sites. You will have both a local database for each of your sites and a central database that provides a comprehensive overview of all your sites.

In practice, the system is first set up at a pilot site. Following a testing phase, either Actemium or your Information Systems Department then rolls out the MES solution at the other sites.

Can I implement an MES/MOM system without calling on an integrator?

Your IS department can develop an MES/MOM software package in-house. However, when you call on Actemium, you have the benefit of customised solutions based on Actemium’s more than two decades of experience.

Building on our numerous project references in all manufacturing sectors, our MES/MOM experts are well versed in all shop floor operations and can propose solutions that address your specific issues.

In terms of methodology, we first roll out the MES/MOM system in a pilot production line or shop. You may then, if you wish, continue the rollout in-house to better take the software package on board. We also offer maintenance contracts that give you the benefit of new software releases and any corrective patches that are issued.

Caption

Contact

Find out more about our MES/MOM solutions and services

With a track record in MES/MOM systems going back 20 years, we are in a position to meet the specific needs of every sector, from food processing to manufacturing to pharmaceuticals. We support you at every stage of your MES/MOM implementation project and support and maintain your solution.

For more info, please contact our MES/MOM team :